Understanding Diesel Injector Failure – Causes, Symptoms & Solutions

- Adith Ramsudh

- Aug 25, 2025

- 3 min read

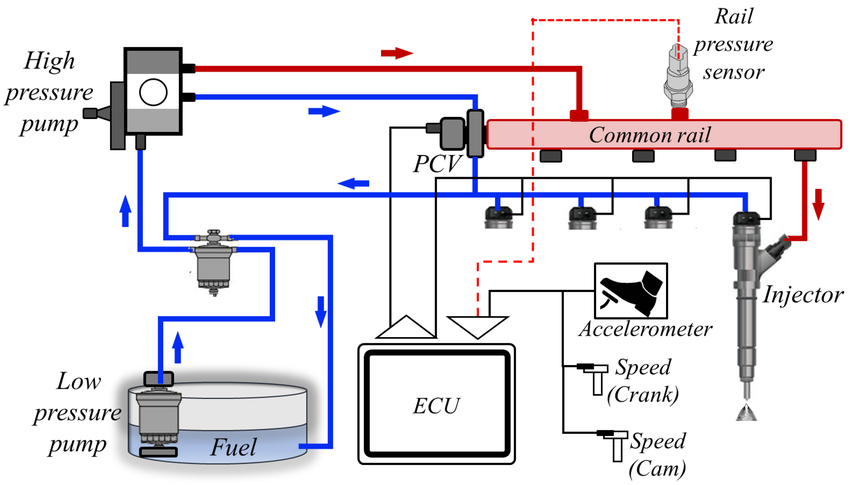

Diesel injectors are some of the most precise and hardworking components in any diesel engine. Operating at pressures up to 2,500 bar, they must deliver atomized fuel in microseconds, thousands of times per minute. Any irregularity in injector function can upset the entire combustion process, leading to performance loss, increased emissions, or even catastrophic engine damage.

At AA Diesel, we’ve seen injector failures across all major systems — Bosch, DENSO, Delphi, and Siemens. In this article, we’ll dive deeper into the causes of injector failure, the symptoms drivers should never ignore, and the advanced solutions available to extend injector life.

The Main Causes of Diesel Injector Failure

Fuel Contamination

Dirt, rust, or even fibers from poor-quality storage tanks enter the fuel system.

Water in diesel encourages corrosion and microbial growth ("diesel bug").

Microscopic particles block spray holes, causing poor atomization.

Incorrect Fuel Handling

Using petrol mixed with diesel (accidental misfuelling) damages injector seals.

Low-quality diesel with poor lubrication accelerates wear.

Injector Overheating

Prolonged idling, poor cooling, or clogged return lines can overheat injectors, leading to stuck needles and burnt tips.

Carbon Build-Up

Caused by leaking copper washers or poor seating during installation.

Leads to “black death,” where injectors are sealed in carbon deposits, often requiring major disassembly.

Mechanical Wear & Tear

After 150,000 – 200,000 km, injector nozzles and needles naturally wear.

Internal seals can fail, causing diesel leakage into oil (raising oil levels dangerously).

Common Symptoms of a Failing Injector

Hard starting or extended cranking

Loss of power and sluggish acceleration

Excessive smoke:

Black = over-fueling / poor combustion

White = unburnt fuel / injector dribbling

Blue = diesel mixing with oil

Diesel knock – sharp metallic ticking sound

Fuel dilution – engine oil level rising due to injector leakage

Misfire under load

Warning lights or fault codes such as P0201–P0204 (cylinder injector circuit errors)

Ignoring these signs often results in piston damage, cracked cylinder heads, or turbocharger failure.

Types of Injector Failures

Sticking Injector Needle – causes poor spray pattern, hard start, and misfire.

Leaking Nozzle – excess fuel delivery, smoke, and washed cylinder walls.

Electrical Failure – solenoid or piezo element burnout in modern injectors.

Mechanical Cracks – from over-torqueing or extreme pressures.

Back Leakage – worn seals allow excess return fuel flow, lowering rail pressure.

Advanced Injector Testing

At AA Diesel, we use specialized test benches to simulate real engine conditions. Our process includes:

Leak-off Testing – checks backflow of each injector.

Spray Pattern & Atomization Test – verifies nozzle efficiency.

Solenoid/Piezo Response Testing – ensures electrical activation is within milliseconds.

Flow Rate Calibration – measures precise delivery amounts.

Ultrasonic Cleaning – removes deposits without damaging precision parts.

Repair vs Replacement – What’s Best?

Repair & Reconditioning

Cost-effective

Involves cleaning, replacing seals, washers, and calibration

Best when injector body is intact and only components are worn

Replacement

Required when nozzles are cracked, piezo/solenoid elements are damaged, or body wear is excessive

More expensive but ensures reliability on heavily worn injectors

At AA Diesel, we provide honest diagnostics — we’ll only recommend replacement if repairs are not viable.

Real-World Example

Recently, a Toyota Hilux D-4D came into our workshop with hard starting, black smoke, and excessive fuel consumption. Testing revealed two injectors leaking excessively due to poor-quality diesel and missed filter changes. After reconditioning and recalibration, the engine regained full power, smoke was eliminated, and fuel consumption dropped by 20%.

Preventing Diesel Injector Failure

Use high-quality diesel and reputable filling stations.

Replace fuel filters at recommended intervals.

Drain water traps regularly.

Avoid long idling, which promotes carbon build-up.

Always use new washers and clean seats during installation.

Get injectors tested every 100,000 – 150,000 km as preventative maintenance.

Why Choose AA Diesel?

With over 30 years of combined experience, AA Diesel specializes in:

✅ Common rail & mechanical injector repairs✅ Denso, Bosch, Delphi & Siemens systems✅ Ultrasonic cleaning & advanced calibration✅ Diesel pump servicing & diagnostics✅ 6-month warranty on injector repairs

📧 infoaadiesel@gmail.com | 📞 082 602 7915

We pride ourselves on professional workmanship, using only quality parts, ensuring your diesel runs reliably and efficiently.

👉 Don’t wait for a breakdown — if you suspect injector trouble, contact AA Diesel today and let us get your vehicle running like new!

Comments